XLPE/HDPE insulated power conductors of Aluminium (Neutral conductor and street lighting conductor if and when necessary) are laid together (twisted) around a high tensilegalvanized steel (Aluminium Alloy may be used) insulated or bare messenger wire to form the Aerial Bunched Cable. This assembly is directly strung on to distribution pole/towers by means of standard hardware available in the market, but care shall be taken to render the messenger wire completely insulated from Earthing at any point of distribution in case of HT ABC.

MV AB cables are highly reliable and insulation has been developed to withstand extreme cold and intense sunlight. Disturbance and faults occur five to ten times more often in open wires lines than in AB cable lines. There is no risk in touching the live cable and the insulation reduces the number of short circuits and overvoltage faults in overhead cables during thunderstorms. Streets can be lit only at little extra cost by adding a Street Light Cable to ABC for lighting. The cable can be supplied with one or two insulated conductors for street lighting.

11 KV & 33 KV Aerial Bunched cables are used for power distribution in cities where ground space is constrained.

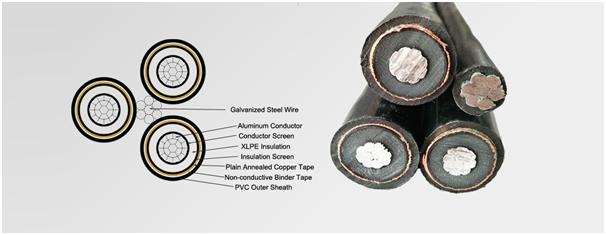

Circular compacted stranded Aluminium conductor.

Conductor construction and testing comply to IS 8130-1984 as amended up to date & as per IEC: 60228.

Screened by an extruded semi conducting layer – XLPE Insulated.

XLPE (The XLPE (Cross-linked Polyethylene) insulation is black in colour and is stabilized against deterioration caused by exposure to direct sunlight and ultraviolet radiation. XLPE is cross-linkable low-density polyethylene, which is made thermo set by special formulation from base polymer of thermoplastic low-density polyethylene. XLPE combines the best electrical properties of LDPE and superior thermo mechanical properties.)

The insulation screening shall consist of two parts; namely metallic & non-metallic.

Non-Metallic Part- Screened again by an extruded layer of semi conducting compound.

Metallic Part – Copper tape screen.

Coloured polyester strip Red, Yellow and Blue, under copper tape

Over the metallic screen the Cable shall be provided with extruded Type ST2 PVC outer sheathor Polyethylene which shall be Black in colour.The Outer Sheath shall either be printed with figures 1 ONE, 2 TWO and 3 THREE corresponding to the three different phases.

Three XLPE insulated screened cores are bundled around the galvanized steel wires in a right hand lay.

Basic design to IEC 60502 / AS/NZS 3599-1 standards

IS:7098 (Part-II)-2011 and its amendment: Specification for Cross linked polyethylene insulated thermoplastic sheathed Cables- for working voltages from 3.3 KV up to and including 33 KV.

IS: 8130-1984 and its amendment: Specification for Conductors for Insulated Electric Cables.

IS: 398 (Part-IV)-1994 and its amendment: Specification for Aluminium Conductors for overhead Transmission purposes: Aluminium Alloy Stranded Conductors (Aluminium-Magnesium- Silicon type)