Instrumentation cables are multiple conductor cables that convey low energy electrical signals used for monitoring or controlling electrical power systems and their associated processes.

These cables are used in diverse applications within industrial process manufacturing plant for control, communication, data (analog/digital) and voice transmission signals, industrial signaling and process control circuit required typically in process industries, oil, gas & petrochemical industry, fertilizers, cement, steel etc.

Introduction of microprocessor based/computerised instrumentation has demanded stringent quality requirements along with special electrical parameters for instrumentation cables. Very low level electrical signals pass between measuring end and display units/controllers which are situated far off. These low level signals are prone to external noise pickups and heavy silenuation during transmission. All this means that the cables to be used for instrumentation should be designed and manufactured very carefully, Suraj Cables with its meticulous efforts in maintaining quality, stringent in process control during manufacture and the knowledge of cable designing, is proud to say that it is capable of supplying instrumentation cables meeting any Indian/International standard or a specific requirement desired by project authority.

Instrumentation cables come with or without flame retardant properties and are suitable in process control, A/D converters and other modern microprocessor-based instrumentation circuits. These cables are designed to offer excellent resistance to noise and induction phenomena encountered in instrumentation circuits.

Voltage grade: 650/ 1100 Volts (Uo/U).

Conforming to standard specifications such as IS: 5608 (Parts I, II, III), BS 5308 (Part I), BS 1584 (Parts I, II, III), IEC 189-5 (Part III), BS 6360, BS 5099 (Part II).

Multi-core, multi-pair or multi-quad laid up concentrically or in units.

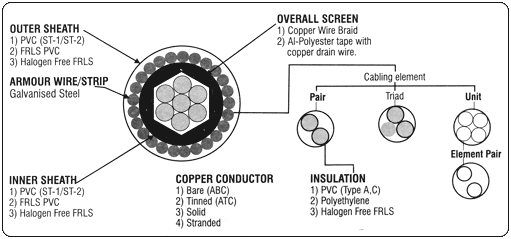

Solid or stranded, tinned, bare or silver-plated annealed, high conductivity EC grade copper, sizes ranging from 0.5 sq. mm to 2.5 sq. mm.

PVC, Solid PE or special thermoplastic materials, heat resistant PVC with an operating temperature range of 85ºC to 105ºC. Halogen free polymeric or elastomeric insulation may also be provided. Core identification through colour coding or character printing.

One or more Plastic Tape

Pairs or Quads can be individually or collectively screened or both. Screening with Copper or Aluminium Mylar Tape, Copper Wire or Aluminum Wire.

Drain Wire of solid or stranded, bare or tinned copper wire normally provided with both individual and overall screening.

Cables can be armoured with galvanized steel wires and strips or double helical steel tape.

PVC of Black or Grey colour. Heat Resistant, FRLS PVC Sheathing, Halogen Free Polymeric or Elastomeric sheathing also available.

Communication Pairs, Bicolor Extrusion, Band marking can be provided on request. Designed to combat all the basic types of noise which affect process instrument signals namely static, magnetic disturbance, manmade noise and cross-talk. Reference specifications for testing are IS: 10810, ASTMD2863, ASTMD2843, IEC-754(I), VDE 0815, VDE 0207 (PT5), IEE383, SS-424-14-75 (F3), VDE0207 (Part IV), VDE0472, IEEE Transit No.467 and as per customer’s requirement.