Suraj Cables Multicore Flexible Cables have a wide range of applications in machine tools, appliances, control panels, machinery & industries of every nature.

The PVC insulated cores that use 99.97% pure bright electrolyte grade copper conductors come with high insulation resistance & dielectric strength.

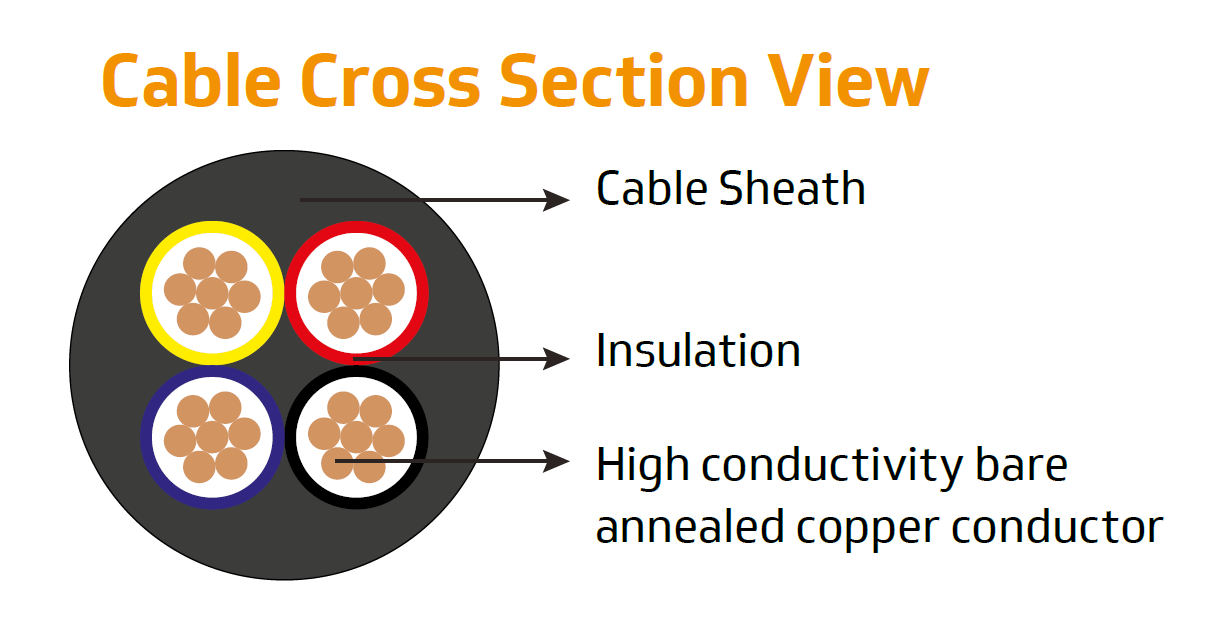

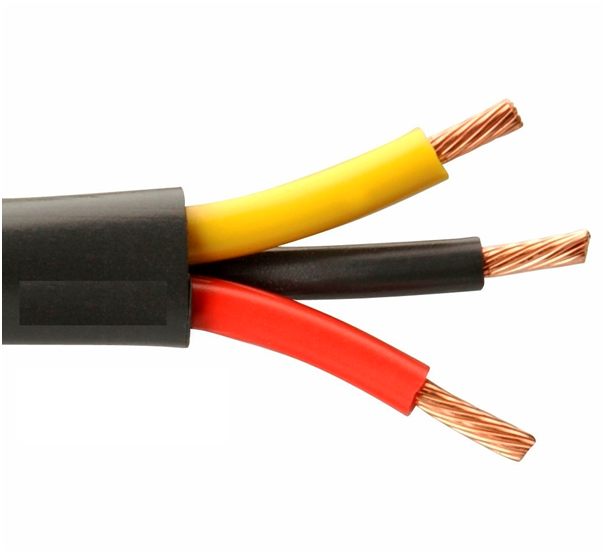

The inner cores are coded for ease of identification as per national/international coding practices. The sheathing is provided with a specially formulated PVC compound to facilitate not only ease in stripping but also to withstand mechanical abrasion while in use. These PVC compound used for insulation & sheathing have high oxygen & temperature index which help in restricting the spread of fire even at high temperature.

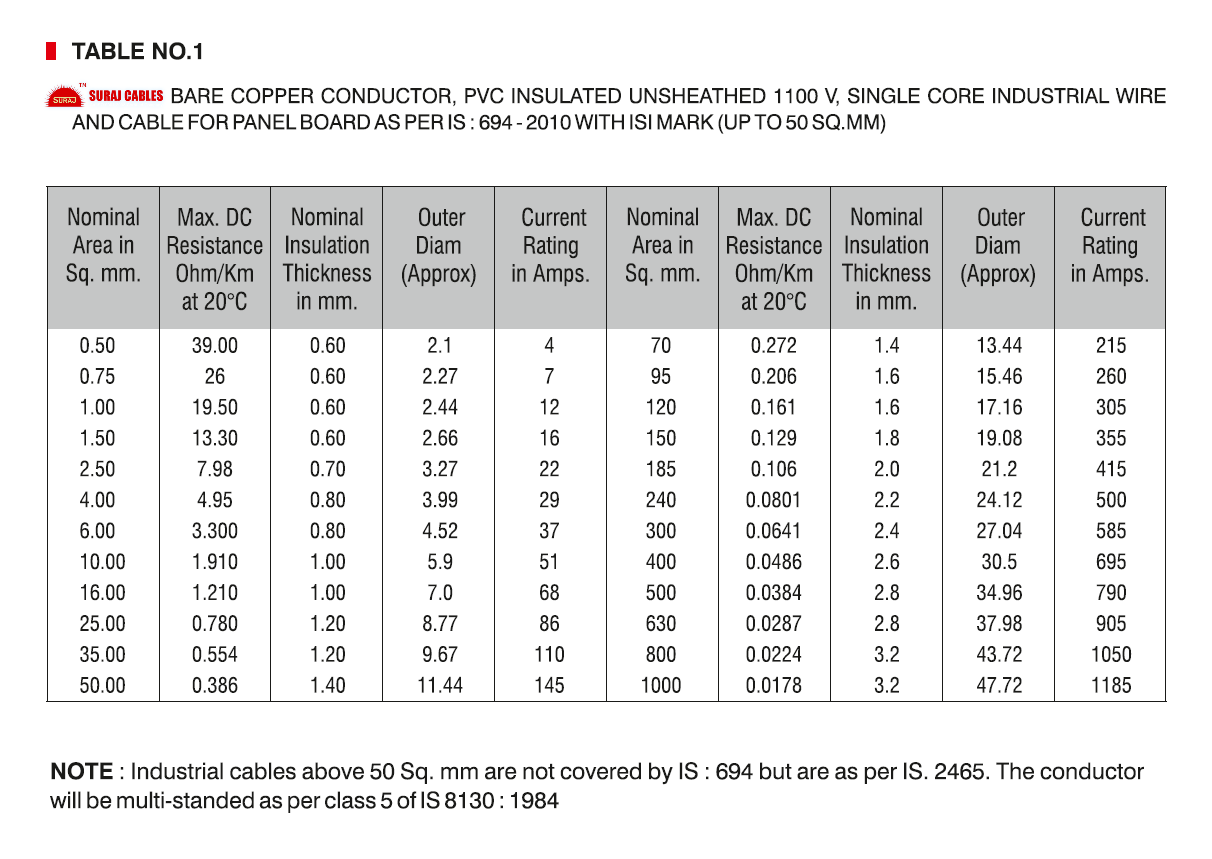

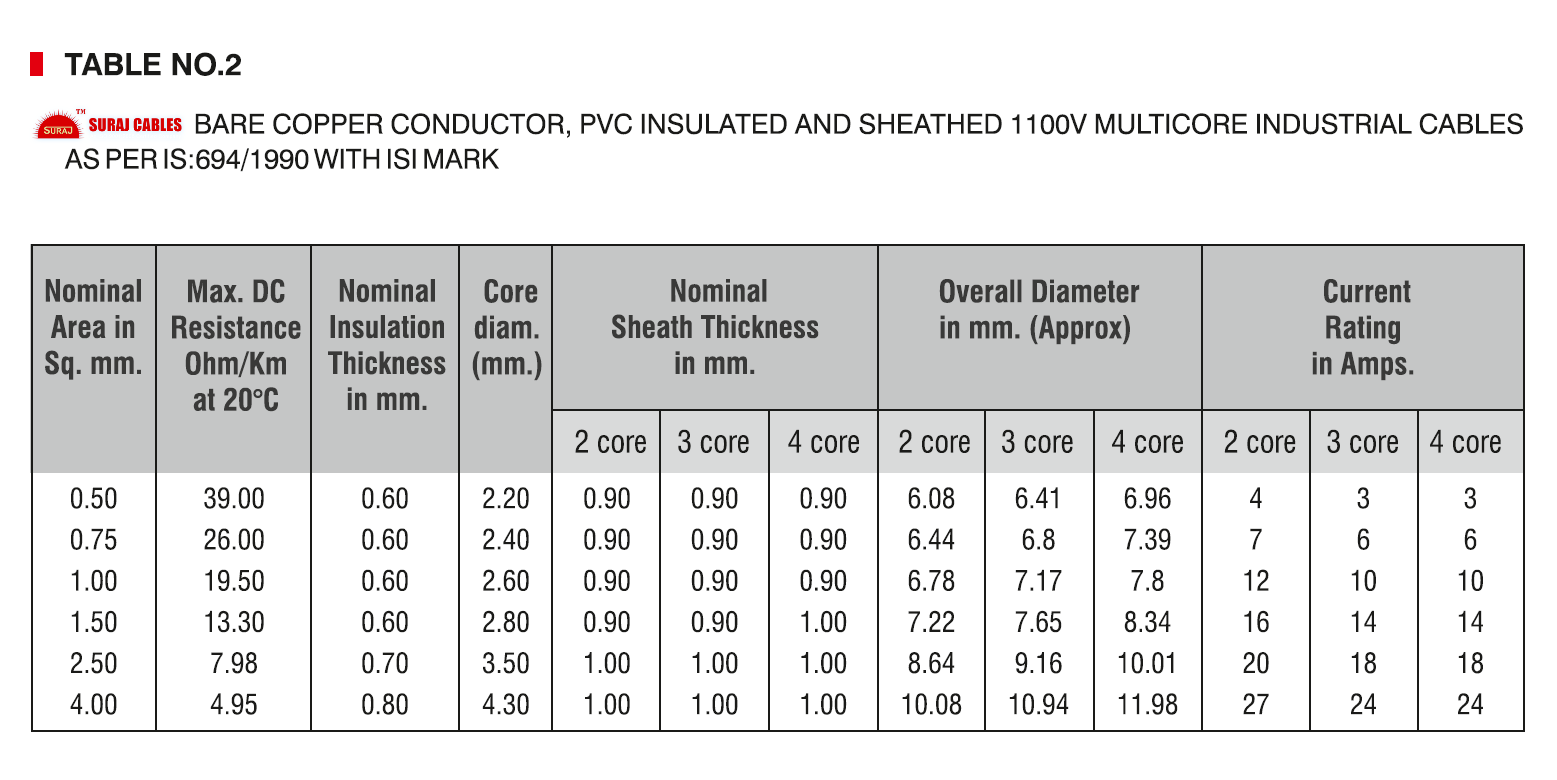

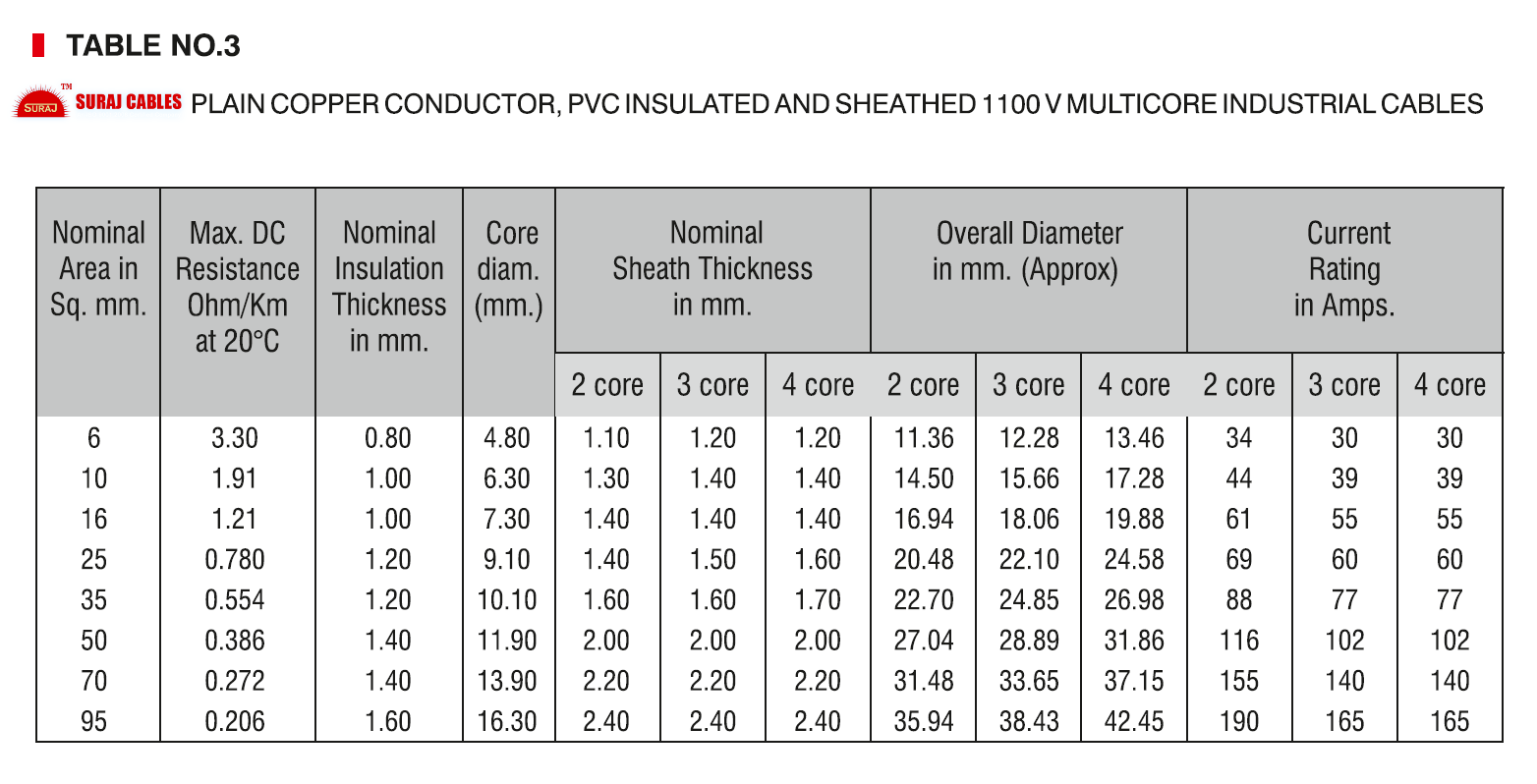

These cables are manufactured as per IS 694 : 1990, in sizes from 0.5 sq. mm. to 50 sq. mm. in single core & in size 0.5 sq. mm. to 4 sq. mm. up to 5 cores. These sizes carry the ISI mark & are duly approved by FIA/ TAC.

At the core of Suraj Cable’s Multicore Round Cables is electrolytic copper conductor with 99.97-99.99% purity and greater than 100% conductivity as per IACS (International Annealed Copper Standard), fully annealed to impart the desired softness / pliability in class 1 conductor and extra flexibility in Class 2 and 5 conductors. Correct diameter, perfect circularity, mirror finish and fine metallurgical structure constitute the conductor characteristics. Class 2 and 5 conductors are stranded / bunched into a compact, cohesive and uniform conductor.

The PVC insulation is a specially formulated compound that has high insulation resistance, thermal stability and exceptional flame-retardant properties, suitable for installation in environs of high temperature and adverse condition. The insulation is applied on a state-of-the-art PLC based insulating line that ensures correct diameter / thickness and concentricity, further enhancing the reliability and longevity of the cable.

Red/ Yellow / Blue / Black /Green

The required number of cores in specified colours, are laid up with proper lay and optimum tension to form an assembled cable that retains the circular shape and does not allow the cores to open or twist out of shape during further processing. The laying up is carried out in an imported machine which applies uniform tension on all the cores resulting in a compact round assembly, correct laid up diameter, essential for maintaining uniform sheath thickness.

It is provided to protect the insulated cores from mechanical damage. The sheathing compound is specially formulated FR compound which combines superior mechanical strength and the desired flexibility to withstand rigorous use involving impact and abrasion and It is easily separable from cores.

Right from the beginning, Quality Assurance has been the cornerstone of Suraj Cables and quality philosophy, embedded in the material, manufacturing process and supply chain. This commitment is reflected in ISO 9001:2008 accreditation and maintained by ceaseless inspection, checks and testing right from the raw material stage through manufacturing to dispatch stage.